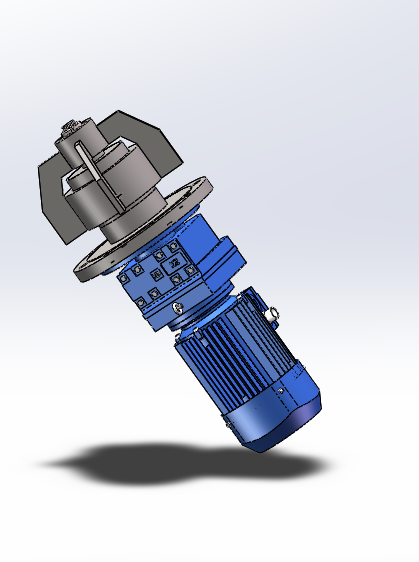

Imagine you go into the lab and hear your magnetic agitator making a strange sound. This can make you feel worried and slow down your work. You can stop most problems like this with regular care and easy checks. Studies show that taking care of magnetic drive stirrers saves money on repairs and helps your equipment last longer. Good brands like Tengyu give strong help, so it is easier to keep your tools working well. If you take care of your equipment early, it will work well every day.

Key Takeaways

Look at your magnetic agitator every day to spot leaks and damage early. Check it often so you can fix problems fast.

Clean the stirrer plate and stir bars after each use. This stops dirt from building up and helps it work well.

Put the right oil on moving parts every day. This lowers rubbing and helps your equipment last longer.

Check bolts and electrical wires every week. This stops shaking and keeps everyone safe.

Watch your agitator while it is working. Listen for strange sounds or shaking that could mean trouble.

Plan a big check-up once a year for deep cleaning and to change old parts. This keeps your agitator working its best.

Pick the right stir bar size and speed for your samples. This helps mix things well and stops problems.

Keep the area around your agitator neat and clean. This keeps away dust and dirt.

Magnetic Agitator Daily Care

Taking care of your magnetic agitator every day helps stop problems. This keeps your equipment working well. You can use a simple routine to help your magnetic drive stirrers last longer.

Visual Checks

Look at your agitator closely each morning. This helps you find problems before they get worse.

Leaks and Wear

Check for leaks near the seals or gaskets. Look for worn spots on the impeller, shaft, and moving parts. If you see damage or fluid in the wrong place, stop and fix it right away. Leaks can cause bigger problems and might ruin your samples.

Coupling Alignment

Check that the coupling between the drive and stirrer is straight and tight. If it is not lined up, it can make noise or shake. It can even break the agitator. If the coupling looks wrong, fix it before you start.

Tip: Looking at your agitator every day is very important. This helps you find damage or wear early.

Cleaning After Use

Cleaning after you use the agitator is important. It keeps your equipment clean and free from dirt.

Stirrer Plate

Wipe the stirrer plate with a soft, wet cloth. Clean up any spills or messes right away. A clean plate helps the stir bar spin well and keeps dirt out.

Stir Bars

Take out the stir bars and wash them with mild soap and water. Dry them fully before putting them back. Picking the right stir bar for your job helps mixing and lowers wear.

Note: Cleaning your agitator after each use keeps it working well and stops contamination.

Lubrication

Lubrication helps your agitator run quietly and smoothly. You should check this every day.

Fluid Levels

Check the fluid levels before you turn on the agitator. If the fluid is low, it can hurt the blades and seals. Always make sure there is enough liquid to cover the blades. This step stops damage and helps mixing.

Lubricant Type

Use the lubricant the maker suggests. Put it on the bearings and moving parts if needed. This lowers friction and helps the agitator last longer. If the lubricant looks dirty or low, change it right away.

Lubricating bearings and moving parts often lowers friction.

Checking seals and gaskets for leaks stops fluid loss.

Watching the motor helps you stop overheating.

Alert: Lubricate every day to avoid expensive repairs and lost time.

Other Daily Tips

Keep the area around your agitator clean and dust-free. Dust can get inside and cause problems. Store your agitator in a dry, cool, and clean place to help it last longer.

Always check that the agitator is the right distance from the vessel. This helps the stir bar spin without slipping or jumping.

You can use this daily checklist to keep your magnetic agitator working well:

Task | What to Check | Why It Matters |

|---|---|---|

Visual Inspection | Leaks, wear, alignment | Stops damage and failures |

Cleaning | Stirrer plate, stir bars | Keeps it working well |

Lubrication | Fluid levels, lubricant type | Lowers friction and wear |

Environment | Dust-free, correct setup | Helps it last longer |

If you follow these steps, your magnetic drive stirrers will work better and last longer.

Weekly & Monthly Maintenance

Doing weekly and monthly checks helps you find problems early. These steps help your magnetic agitator work safely and well.

Fastener Checks

Loose fasteners can cause trouble. Check all bolts and electrical connections every week.

Bolts

Bolts keep your stirrer together. If bolts get loose, you might feel shaking. Shaking can hurt the machine over time. This can break the machine’s parts. Broken parts make your equipment not last as long.

Loose bolts or fasteners can cause shaking.

Shaking for a long time can hurt the machine.

Hurt parts can break the agitator’s structure.

Broken parts make the agitator not last as long.

Tip: Use a wrench to check each bolt. Tighten any loose ones. Do this every week.

Electrical Connections

Check all electrical connections to make sure they are tight. Look for wires that look worn out. Loose wires can stop the stirrer or cause danger. Watch for wires that look frayed or burnt. If you see bad wires, change them right away.

Alert: Never touch electrical parts when the machine is plugged in. Always turn off the power first.

Component Wear

Parts inside your magnetic drive stirrers can wear out. Finding problems early helps you avoid big repairs.

Impeller

The impeller moves the liquid in your vessel. Listen for strange sounds like grinding or squealing. These sounds mean the impeller or bearings may be wearing out. Too much shaking can also mean something is wrong.

Strange sounds or shaking when running.

Grinding, squealing, or rattling noises.

Too much shaking means parts are worn or not lined up.

If you hear these signs, stop the machine and check the impeller. Change broken parts as soon as you can.

Shaft

The shaft links the impeller to the drive. Watch for shaking or wobbling when you use it. A bent or worn shaft can make the stirrer work badly. Sensors can help you find shaft or bearing problems early.

Grinding noise means a bearing is bad.

Too much shaking means something is not lined up.

Sensors can find bearing or gearbox problems.

Sensors can also find shaft problems.

Note: Check even small changes in sound or movement right away. Acting fast can stop big problems.

Environment

The area around your stirrer matters. Keeping it clean helps your equipment.

Dust Control

Dust can get inside your magnetic agitator and cause damage. Wipe surfaces and vacuum every week. Use covers when not using the machine.

Contaminant Prevention

Keep chemicals and liquids away from the control panel. Spills can cause rust or electrical problems. Store cleaning supplies and chemicals somewhere else.

Maintenance Task | Frequency | What to Look For |

|---|---|---|

Bolt Tightening | Weekly | Loose or missing bolts |

Electrical Check | Weekly | Frayed wires, loose plugs |

Impeller Inspection | Monthly | Noises, vibration, wear |

Shaft Monitoring | Monthly | Wobbling, misalignment |

Dust Cleaning | Weekly | Dust on surfaces, covers |

Spill Prevention | Weekly | Clean, dry surroundings |

Callout: A clean and cared-for area helps your stirrer last longer and work better.

By doing these weekly and monthly steps, you protect your magnetic drive stirrers. You also stop surprise breakdowns. Your equipment stays safe and works well every time.

Annual System Inspection

Plan to check your magnetic agitator once every year. This helps you find hidden problems. It also keeps your equipment working well. Yearly checks can show damage that daily or monthly checks might miss.

Deep Cleaning

Begin your yearly check by cleaning deeply. Take apart the main parts of your agitator. Clean each part carefully. Remove any buildup from the magnets, impeller, and housing. Use soft brushes and safe cleaners.

You should set a cleaning schedule for your magnets. This depends on how much tramp metal your work gets. MPI says to check magnets no more than eight hours after you start using them. You should also check after each product change or production run. After that, check every eight hours or sooner.

Clean magnets always work better. If there is no tramp metal on the magnet, it works its best.

Always look for trapped metal or dirt. Clean magnets help your magnetic drive stirrers work their best. Dry all the parts before you put them back together.

Parts Replacement

Check for old or broken parts during your inspection. Look at seals, bearings, and gaskets for cracks or leaks. Check the impeller and shaft for signs of wear. Change any part that looks damaged or worn out.

Only use real Tengyu parts when you replace something. These parts fit right and last longer.

Write down every part you change. This helps you keep track of your equipment’s health.

Tip: Using real parts from good brands like Tengyu keeps your agitator safe and strong.

Performance Testing

After cleaning and changing parts, test your agitator. Run it with water or another safe liquid. Listen for odd sounds. Watch for shaking or leaks. Make sure the stir bar spins smoothly and the speed is correct.

Test Step | What to Check | Why It Matters |

|---|---|---|

Start-up | Smooth operation | Finds hidden problems |

Noise Level | Unusual sounds | Shows wear or damage |

Leak Check | Around seals and joints | Prevents fluid loss |

Speed Test | Stir bar movement | Ensures proper mixing |

Write down what you find in your tests. Keep these notes for next time. This helps you see if anything changes later.

Note: Do your yearly check at the same time each year. Set reminders so you do not forget this important job.

A yearly check keeps your magnetic agitator working great. You can stop big repairs and keep your lab safe. Good notes and regular checks help your magnetic drive stirrers last longer and work better.

Efficiency Optimization

You can help your magnetic agitator work better by making it more efficient. Using the right tools and habits saves energy. It also helps your equipment last longer. This part will show you how to get the best from your stirrer.

Monitoring

Watch your stirrer every time you use it. Checking it in real time helps you find problems early. Many new magnetic drive stirrers have smart sensors. These sensors check things like speed, temperature, and shaking. If something changes, you can fix it before it stops your work.

Tip: Try using IoT-enabled sensors to watch your stirrer. These sensors send alerts if there is a problem. You can fix things quickly and stop bigger issues.

Write down what happens each time you use your agitator. If you see it using more power or making new sounds, you can plan repairs before it breaks. This habit helps make your lab work better.

Upgrades

You can make your equipment work better by upgrading it. Many labs use new propeller shapes and smart controls now. These upgrades save energy and lower costs.

Here are some upgrades that help save energy:

Upgrade Type | Description |

|---|---|

New propellers use less power but still mix well. | |

Variable Frequency Drives (VFDs) | VFDs let you change the speed for each operation. This saves energy. |

Smart Technologies | Real-time monitoring and predictive tools help you plan maintenance. |

New impeller designs use less power.

Retrofit kits let you update old systems without buying new ones.

Lighter parts and easy-care pieces help save money.

New magnetic heating agitators have also changed. IoT sensors and automation give you more control. Better materials and coil designs help heat and mix faster. These changes make your work easier and more efficient.

Preventive Maintenance

You can keep your stirrer working well by checking it often. Preventive maintenance means you fix small problems before they get big. This keeps your work going and stops surprise breakdowns.

If you follow a schedule, you can fix things when you are not busy. This way, you do not stop work when you need your magnetic agitator most. Predictive tools help you know when parts might break. You can change them before they cause trouble.

Note: Preventive maintenance means less downtime and more trust in your equipment. You spend less time fixing and more time working.

Setting the right speed and time for each job also helps. This lowers wear and saves energy. When you use these steps, you make your stirrer work better and get great results.

Safety Precautions

You should always follow safety steps when using a magnetic agitator. These steps keep you, your coworkers, and your equipment safe. Staying careful helps you avoid accidents and keeps your workspace safe.

Grounding

Check if your magnetic agitator is grounded before you start. Grounding stops electric shocks and protects the machine from power surges. If your magnetic stirrer has a hotplate, make sure the cord has a ground pin. Plug it into a grounded outlet. Never use a broken cord or adapter. If you see sparks or feel a shock, stop using the agitator and tell your supervisor right away.

Tip: Always look at the power cord and plug before you use it. Change any broken parts to keep your equipment safe.

Overload Prevention

Do not put too much weight on your agitator. Too many samples or heavy loads can make the motor get too hot. This can break the agitator and cause a fire. Use the right vessel size and stir bar for your job. Follow the maker’s rules for speed and load. If you hear odd sounds or see the agitator slow down, turn it off and check for problems.

You can stop overload by doing these things:

Use the right vessel size for your agitator.

Do not go over the speed limit.

Watch for signs of overheating, like burning smells or hot surfaces.

Let the agitator cool down after long runs.

Operator Training

Training helps you and your team use magnetic agitators safely. You should learn how to handle magnets, use tools, and spot risks. Training teaches you about safe handling, using safety gear, and what to do in emergencies.

Here are some important safety steps to follow:

Wear gloves, safety goggles, and steel-toed boots.

Use magnetic lifters or team lifting for heavy items.

Stay away from strong magnetic fields.

Store magnets on stable surfaces and label storage areas.

Training Program | Focus Area |

|---|---|

MAGNET TRAINING FROM MLTUS | Learn how to use magnets and best ways to get good results. |

CRANE OPERATOR AND MAINTENANCE SEMINAR | Find out why magnets fail and how to stop it. |

ONSITE MAGNET CONTROLLER TRAINING | Learn about controller parts and how to fix common problems. |

MAGNET TESTING 101 | Learn how to test magnets and find problems early. |

Alert: Training keeps you safe and helps you find problems before they get worse.

If you follow these safety steps, you lower the chance of accidents and keep your magnetic agitator working well. Good training and careful habits help you work with confidence every day.

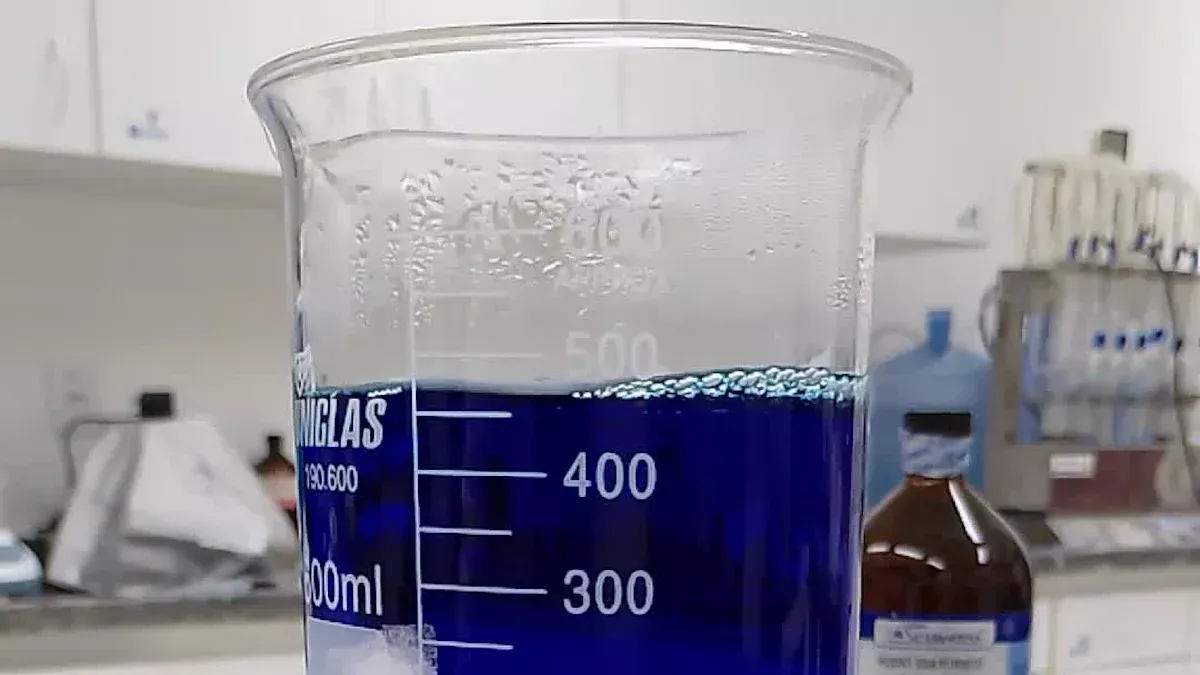

Magnetic Stirrer with Hotplate

A magnetic stirrer with hotplate helps you mix and heat liquids at the same time. You can use it in science labs, classrooms, or even at home for simple experiments. To get the best results, you need to set up, use, and clean your device the right way.

Setup

You should always start by placing your magnetic stirrer with hotplate on a flat, sturdy surface. This keeps the device steady and stops it from shaking during use. Make sure there is open space around the device. Good airflow helps prevent overheating.

Next, pick the right stir bar for your liquid. If you have a thick or large sample, choose a bigger or stronger stir bar. Place your vessel on the hotplate so the bottom sits about 1 cm above the plate. This helps heat and mix your sample well.

Before you begin, adjust the hotplate to the temperature you need. Let it reach the right heat before you add your sample. Always start stirring at a low speed. Slowly increase the speed to avoid splashing and to form a good vortex.

Tip: Never rush the setup. Careful steps help your magnetic stirrer with hotplate last longer and work better.

Operation

During operation, you need to watch your device closely. Check that your vessel sits in the center of the hotplate. If it moves, you might get uneven heating or mixing. Listen for strange sounds. Loud noises can mean the stir bar is not lined up right.

Keep an eye on the temperature. If it gets too hot, your sample can break down or become unsafe. Many magnetic stirrer with hotplate models shut down if the temperature goes outside the safe range. Always use the right settings for your experiment.

You should also make sure the stir bar stays in place. If it slips or jumps, stop and fix it before you continue. This keeps your mixing smooth and safe.

What to Monitor | Why It Matters |

|---|---|

Temperature | Prevents overheating |

Vessel Placement | Ensures even mixing and heating |

Stir Bar Alignment | Stops noise and slippage |

Note: Careful operation helps you avoid mistakes and keeps your magnetic stirrer with hotplate in top shape.

Cleaning After Use

When you finish using your magnetic stirrer with hotplate, clean it right away. First, turn off the device and let it cool. Remove the stir bar from the vessel. Wash the stir bar with soap and water to stop anything from sticking to it. Use a brush and a disinfecting solution if you need to scrub off tough spots.

If you plan to sterilize the stir bar, keep it in a disinfecting solution until you are ready. Protect the clean stir bar from dust and dirt. Clean your beakers and flasks before you use them again.

Wipe the hotplate with a soft, damp cloth. Make sure no spills or stains remain. Dry all parts before you store them. Clean tools work better and last longer.

Alert: Cleaning after every use keeps your magnetic stirrer with hotplate safe and ready for your next experiment.

Troubleshooting

Vibration

You may notice your stirrer shaking or vibrating during operation. This can make you worry about the safety of your equipment. Vibration often points to a problem with the mixing process or the setup of your stirrer. You should check for these common causes:

The tank level can affect how your stirrer works. If the liquid is too low or too high, the stirrer may not mix well and can start to vibrate.

The type of liquid in the tank matters. Thick or sticky liquids can create more force on the stirrer, leading to vibration.

Hydraulic forces from mixing can cause the stirrer to shake at different speeds and strengths.

To diagnose vibration, you need to look at where the shaking starts. You can use sensors to measure how much the stirrer moves. Sometimes, you need to check if the support structure is strong enough. If you find that the stirrer vibrates at certain speeds, you may have a resonance problem. You can fix this by changing the speed or adding more support.

Tip: Always check your stirrer’s alignment and make sure it sits flat on the surface. A well-placed stirrer helps reduce vibration.

Noise

Strange noises from your stirrer can signal trouble. You might hear grinding, squealing, or rattling sounds. These noises often mean that parts inside the stirrer are worn out or not lined up right. You should stop the stirrer and check for loose bolts, worn bearings, or a bent shaft.

Sometimes, the stir bar can hit the sides of the vessel if it is not centered. This makes a loud clacking sound. You can fix this by placing the vessel in the center of the stirrer plate and making sure the stir bar is the right size for your mixing job.

Alert: Never ignore new or loud noises. Quick action can prevent bigger problems with your stirrer.

Mixing Issues

If your stirrer does not mix well, you may see layers in your liquid or notice that the solution is not even. Mixing issues can happen if the stir bar is too small, the speed is too low, or the vessel is not the right shape. You should always pick the right stir bar for your sample and adjust the speed to get a strong vortex.

Check if the stirrer plate is clean and dry. Dirt or spills can stop the stir bar from spinning smoothly. If you see the stir bar jumping or slipping, try lowering the speed or using a different vessel.

Here is a quick checklist for troubleshooting common issues with mixing:

Is the stir bar the right size and shape?

Is the vessel centered on the stirrer plate?

Is the speed set correctly for your liquid?

Is the stirrer plate clean and dry?

Note: Good mixing depends on the right setup and regular care of your stirrer.

If you follow these steps, you can solve most problems with your stirrer. Regular checks and quick fixes help your mixing stay smooth and your equipment last longer.

Seal Leaks

Seal leaks can cause big problems for your magnetic agitator. You might see liquid dripping from the seals or notice wet spots around the base. If you ignore leaks, you risk damaging the motor, bearings, and other parts. You also risk contaminating your samples.

You should check the seals every time you use your agitator. Look for cracks, splits, or loose fittings. If you see any liquid near the seals, stop the agitator and inspect it right away. Use a flashlight to look for hidden leaks. Sometimes, small leaks only show up when the agitator runs at high speed.

Tip: Always keep a spare set of seals in your lab. Quick replacement helps you avoid downtime.

Here are some common causes of seal leaks:

Worn or old seals

Incorrect installation

Chemical attack from harsh liquids

High pressure or temperature

You can prevent seal leaks by following these steps:

Use seals made for your specific agitator model.

Install seals carefully and follow the manufacturer's instructions.

Avoid using strong acids or bases unless your seals can handle them.

Do not run the agitator above its recommended speed or temperature.

If you find a leak, you should:

Turn off the agitator and unplug it.

Remove the vessel and clean up any spilled liquid.

Take out the old seal and check for damage.

Put in a new seal and make sure it fits tightly.

Test the agitator with water before using it with chemicals.

Here is a quick table to help you spot seal problems:

Symptom | Possible Cause | What You Should Do |

|---|---|---|

Dripping liquid | Worn seal | Replace the seal |

Wet base | Loose fitting | Tighten the seal |

Bubbles | Chemical attack | Use chemical-resistant seal |

Noise | Misaligned seal | Reinstall the seal |

Alert: Never ignore a seal leak. Even a small leak can lead to bigger problems.

You should keep a log of seal replacements and leaks. This helps you spot patterns and plan maintenance. If you see frequent leaks, you may need to upgrade to better seals or change your mixing process.

Seal care keeps your agitator safe and your samples clean. Regular checks and quick action help you avoid costly repairs.

You can help your magnetic agitator last by doing regular checks. Do daily, weekly, and yearly routines to keep it in good shape. Use magnetic drive stirrers and magnetic stirrer with hotplate for mixing and heating jobs. Always clean your magnetic stirrer with hotplate after you finish using it. Check bolts, seals, and wires to make sure they are safe. If you need to fix something, use real Tengyu parts. Put safety first every time you use a magnetic stirrer with hotplate. Look at your schedule often and ask Tengyu for help if you are not sure. Start now and make a habit of good care.

️ Taking care of your magnetic stirrer with hotplate helps it work well and last longer.

FAQ

How often should you clean your magnetic agitator?

You should clean your magnetic agitator after every use. This stops dirt and chemicals from building up. Clean stir bars and plates help your agitator work better and last longer.

What signs show your agitator needs maintenance?

Watch for strange noises, shaking, leaks, or slow mixing. These signs mean you should check your agitator. Fixing small problems early helps you avoid bigger repairs.

Can you use any lubricant for your agitator?

No. Always use the lubricant recommended by the manufacturer. The right lubricant protects moving parts and helps your agitator run smoothly.

Why does your stir bar keep slipping or jumping?

A stir bar may slip if it is too small, worn out, or not centered. Check the vessel placement and use the correct size stir bar for your job.

What should you do if you see a leak?

Alert: Turn off your agitator right away. Check the seals and replace any damaged parts. Clean up spills to keep your workspace safe.

How do you prevent dust from damaging your agitator?

Keep the area around your agitator clean. Use a cover when not in use. Wipe surfaces weekly to stop dust from getting inside.

Is it safe to leave your magnetic agitator running overnight?

You should not leave your agitator running without supervision. Unattended operation can cause overheating or spills. Always follow your lab’s safety rules.