You can find magnetic agitators in many industries today. They help mix things in a safe and clean way. These devices use magnets, not regular seals. This means there is less chance of leaks or getting things dirty. You will see magnetic agitators used in:

Chemical processing

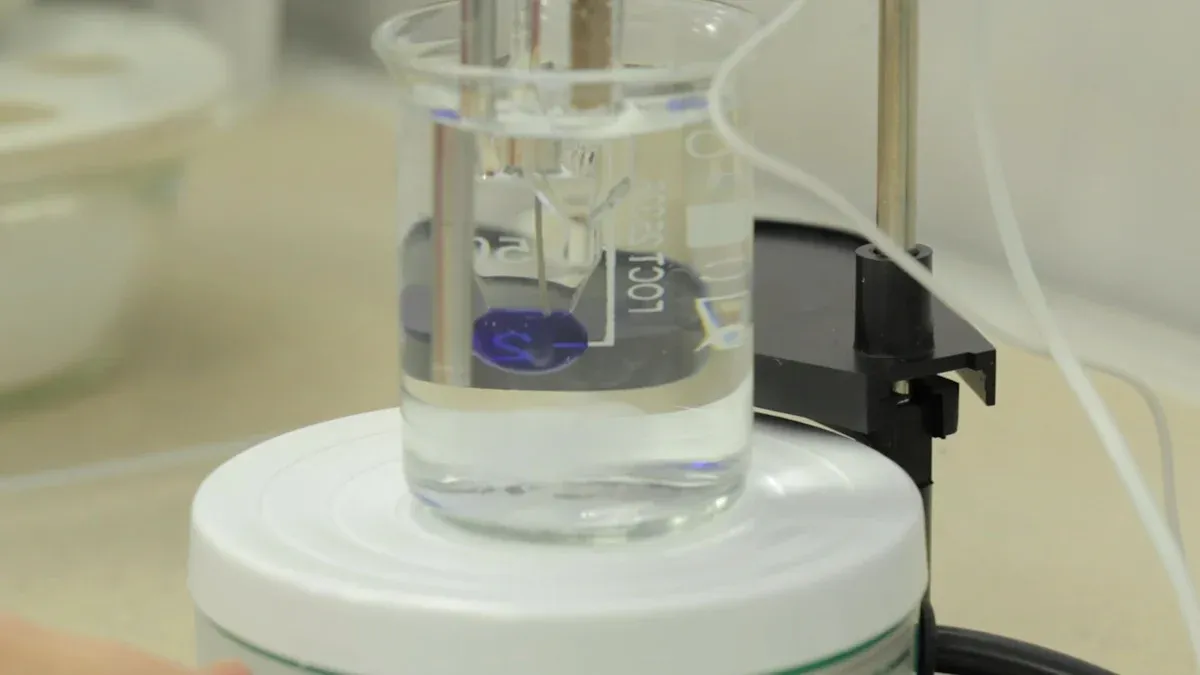

Laboratory research

Pharmaceuticals

Biotech applications

Food processing

Water treatment

High-purity manufacturing

Industrial magnetic agitators make products better and are easy to take care of. You can learn how each industry uses them in the next sections.

Magnetic agitators use magnets, not seals. This lowers the chance of leaks and keeps things clean in many industries. These devices are simple to clean. They are great for places that need strict hygiene, like making medicine or food. Magnetic agitators mix things the same way every time. This helps keep products safe and good in jobs like making drugs or cleaning water. They use less energy and cost less to fix. This makes work faster and cheaper. Industries like biotech and chemical making use magnetic agitators. They like the good control and trust these devices give in careful jobs.

Magnetic agitators are important in making medicine. They help mix things in a clean way. These tools use magnets, not seals. This stops leaks and keeps germs out. You can clean them easily. This makes the process safe and quick.

Here are some benefits:

You can keep your product safe from germs and dust.

You can mix small amounts of liquid and not waste anything.

You can trust the equipment to be clean because it passes tough tests.

Pharmaceutical companies like magnetic agitators for hygiene. They use them to mix creams, ointments, and liquid medicine. The mixing makes every batch the same. This helps with safety and quality. You also save time and waste less. This means you can make more products with less work.

Tip: Magnetic agitators have strong magnets and a closed shell. This keeps your product safe from germs while mixing.

Stopping contamination is very important in making medicine. Magnetic agitators help with this. They do not have seals that can break or leak. This means nothing unwanted gets into your product.

You can also use magnetic separation to take out bad things. This is used in food, dairy, and medicine. It keeps products pure and equipment safe. Magnetic separation can catch and clean things in one step. You can work with big batches fast and use less energy.

A magnetic agitator helps you follow strict safety rules. You can trust it to keep things clean and work well. This tool is now common in medicine and food because it mixes well and stops contamination.

You want your food to taste good and look nice. Magnetic agitators help with this in food factories. They use magnets instead of seals. This keeps your ingredients safe from germs. You can trust these agitators to mix things the same way every time. This helps every batch meet your standards.

Magnetic agitators help you make new foods.

They let you create vegetarian and vegan meat with good texture.

You get strong mixing, so your food stays high quality.

You can control how much mixing happens for each recipe.

Note: Good mixing helps keep your food safe and the same every time.

Food factories must follow strict cleaning rules. Magnetic agitators make this easier. They do not have seals, so you do not worry about leaks or germs. You can use them in places where everything must be very clean.

Here is a table that shows what to look for in clean equipment for food:

Requirement | Description |

|---|---|

Health protection | Keeps food safe for everyone. |

Safe and easy handling | Lets you use equipment without danger. |

Product preservation | Keeps food good while mixing. |

Quick maintenance | Makes cleaning and fixing easy. |

Clean processes | Helps you stop germs from spreading. |

Smooth surfaces | Stops bacteria from hiding. |

Chemical-resistant materials | Keeps equipment strong and safe. |

Uniform joints | Reduces places where germs can hide. |

Ease of inspection | Lets you check for cleanliness easily. |

Prominent separation | Keeps equipment off the floor to lower germs. |

No corners or angles hard to reach | Makes cleaning fast and easy. |

You can clean magnetic agitators quickly. This is important in food factories. You must keep everything clean. Smooth surfaces and even joints help stop bacteria. You save time because cleaning is simple. Magnetic agitators help you feel sure your food meets the best standards.

Chemical manufacturing needs strong mixing. Magnetic agitators give you this strength. They keep your solution mixed all the time. This helps you get the right reaction each time. You can use them for many chemical jobs. Some uses are:

Blending chemicals to make new things.

Keeping solutions even during reactions.

Mixing powders and liquids for better results.

Magnetic agitators work well in tough places. They do not break down fast. You can trust them with strong acids or bases. Many companies have tested these agitators and liked the results.

Case Study | Description |

|---|---|

Case Study 1 | A chemical company used Vanton’s magnetic agitators. They had 30% less downtime because of better sealing and corrosion resistance. |

Case Study 2 | A drug plant used Silverson mixers. They got better mixing and faster batch times. This showed the technology works well. |

Case Study 3 | An industrial site tried SPX Flow’s agitators. They saw the same good results in different tank sizes before using them everywhere. |

You can see magnetic agitators save time. They help your process run smoothly. They also keep mixing the same, no matter the batch size.

Safety is very important in the chemical industry. You want to stop leaks and spills. Magnetic agitators help with this. They have a sealed design. You do not have to worry about chemicals getting out. This keeps your workplace safer.

Feature | Magnetic Agitators | Mechanical Agitators |

|---|---|---|

Mechanical Seals | No | Yes |

Risk of Leakage | Minimal (static seal) | High (prone to wear and tear) |

Maintenance Needs | Low | High (regular maintenance required) |

Environmental Compliance | High (reduces contamination risk) | Moderate (risk of spills) |

You can see magnetic agitators lower leak risks. They need less fixing. This means you spend less time on repairs. You can focus more on making products. In food factories, small leaks cause big problems. The same thing happens with chemicals. Magnetic agitators keep your process clean and safe. You can trust them to protect workers and the environment. These agitators help you follow safety rules. You get better results and feel safe every day.

You help keep water clean and safe for everyone. Magnetic agitators mix chemicals and water in treatment plants. This mixing is called homogenization. It makes sure all water gets the same treatment. You can use magnetic agitators for many steps:

Flocculation: Small particles stick together to make bigger clumps. This helps remove them from water.

Coagulation: Coagulants spread out and help particles join faster.

Disinfection: Disinfectants mix well and touch every germ. This makes water safe to drink.

Magnetic agitators change how water moves in tanks. They make crystals form quickly and stay small. This stops scale from building up in pipes. The table below shows how these agitators help water treatment:

Mechanism/Effect | Description |

|---|---|

Nucleation Rate | Magnetic fields make crystals form fast and stay small. |

Scale Prevention | Magnetohydrodynamic effects help stop and remove scale. |

Hydrodynamic Alteration | Magnetic fields change how water moves and mixes. |

Tip: Good mixing keeps water quality high and equipment working longer.

You need to keep solids moving in water tanks. Magnetic agitators make steady mixing. This stops solids from sinking and keeps them mixed. These agitators help in many ways:

Function | Description |

|---|---|

Chemical Mixing | Chemicals mix well and help with flocculation or pH changes. |

Bio-Solids Management | Solids stay mixed so they break down and do not settle. |

Heat Distribution | Heat spreads evenly, which is important for some processes. |

Oxygen Transfer | Oxygen mixes in better, helping good bacteria live and work. |

You get better results when you use magnetic agitators. They help mix chemicals, manage solids, and keep the right temperature. They also help oxygen mix in, so bacteria can grow. With good mixing, your water treatment works better and is more reliable.

When you work with living cells, you need careful control. Magnetic agitators help you do this. They use a magnetic drive system. This keeps the impeller and motor apart. The design stops leaks. It keeps your cultures safe from germs. You can trust this agitation for sensitive jobs.

Many biotechnology labs use magnetic agitators. Here are some ways they help:

In cell culture and microbiology, you spread out nutrients and gases. This helps cells grow well.

In molecular biology, you mix reagents for PCR and DNA sequencing.

In drug development, you blend compounds during tests and making new drugs.

In bioprocessing, you keep culture mediums even for fermentation and medicine.

Research shows magnetic agitation lowers contamination risks in stirred-tank bioreactors. You can use many speeds for gentle mixing. This helps you meet hygiene rules. It also saves money because the equipment lasts longer.

Tip: Magnetic agitators are great for animal cell culture fermentations. You get better hygiene and less risk of cross-contamination.

You want your work to be safe and smooth. Magnetic agitators help you control each step. Their sealed design keeps your area clean. It stops unwanted things from getting in. You can clean these agitators easily with Clean-In-Place (CIP) systems. This means you spend less time cleaning and more time working.

Magnetic agitation lets you change speed and power for each job. You can handle different liquids and cell types without new equipment. This flexibility helps you get the best results every time.

Benefit | Description |

|---|---|

Aseptic conditions | Keeps your process free from germs |

Easy cleaning | CIP systems make cleaning fast and simple |

Reliable performance | Reduces downtime and keeps results steady |

Flexible operation | Handles many types of agitation tasks |

You can trust magnetic agitators for strong process control. They help you meet high standards in biotechnology. You get safe, clean, and steady agitation for every project.

In labs, you must keep things very clean. Magnetic agitators help you do this. They mix liquids and keep samples safe. You use them to make reactions happen faster. They also help you get samples ready for tests. These tools keep your mixtures pure and free from dirt. Magnetic agitators are gentle, so they do not hurt cells. They also help nutrients spread out in the liquid.

You use magnetic agitators in many ways in the lab. You mix liquids to help reactions go faster. You stir solutions for science experiments. You get samples ready for tests and keep them clean. You stir food for cells so they grow well. You also keep mixtures even, which helps you get good results.

Tip: Gentle mixing keeps cells safe and your samples clean.

You see magnetic agitators in many clean industries. The table below shows where they are used and what they help make:

Industry | Applications |

|---|---|

Pharmaceuticals | IV solutions, vaccines, insulin, injectables, eye drops |

Biotech | Fermentation, cell culture media, protein solutions |

Food & Beverage | High-purity syrups, dairy enzymes, baby food liquids |

Cosmetics & Personal Care | Serums, toners, extracts |

Specialty Chemicals | Ultra-pure fluids, suspensions |

You want your products to stay clean and safe. Magnetic agitators help by using magnets instead of seals. This stops leaks and keeps bad things out. Floating Zero-g technology also helps stop germs from moving between batches.

Magnetic drive technology uses no seals, so there are no leaks or dirty products. You also do not need to fix them as often.

You get more good things from magnetic agitators. You can lift the impeller to drain all the liquid. This means nothing is left behind. You can clean every part, so no germs or chemicals stay. You can change what you make without worrying about mixing things up.

Feature | Benefit |

|---|---|

No seals means less leaking and less risk of dirty products. | |

Impeller levitation | All liquid drains out, so nothing is left behind. |

Effective cleaning design | Cleaning agents reach every part, so cleaning is easy. |

You trust magnetic agitators to keep your process safe and clean. You protect your products, save time, and follow strict rules.

You want to use less energy and spend less money. Magnetic agitators help you do both things. They have motors that save energy and work with special drives. You can change the speed and power for each job. This means you only use the energy you need. The impeller design also helps save power. You get strong mixing but use less energy than old machines. Special impellers help with gas, so you do not need extra machines like compressors.

Motors and drives that save energy use less power.

New impellers give strong mixing with less energy.

Special impellers mean you do not need more machines.

You pay less for electricity and fixing machines. You also avoid leaks and big repairs. Over time, these savings help your business do better.

You want to get the most from every batch you make. Magnetic agitators help you reach this goal. They mix gently and take care of your products. In medicine plants, you keep blends clean and lower the chance of germs. This makes better drugs and helps you follow rules. In biotech labs, gentle mixing helps cells grow and gives you more product, like vaccines. Food makers get better texture and taste, so there is less waste and more good food.

One company had 15% fewer bad batches after using magnetic coupling.

Another lab cut prep time by 20% because cleaning was faster.

One leader made vaccine processing 25% more efficient.

You can run the agitator dry and mix every drop. Easy cleaning and less fixing mean you make more and fix less. With the right mixing, you get more product, save money, and keep things running well.

When you pick Tengyu, you get more than just good mixing. You also get new technology that makes your job safer and easier. Tengyu is special because it has a smart design and cares about what you need.

Tengyu’s agitators do not use seals. This means you do not have to worry about leaks. Old agitators use seals that can break and cause trouble. Tengyu takes away these weak spots. The system keeps liquids inside, even with dangerous or harsh materials. This design makes the mixing process more dependable. You can count on the equipment to keep working without sudden stops or spills. The seal-less part helps you spend less on repairs and keeps your workplace safer.

Tengyu’s seal-less design stops most leaks from happening. You get better dependability and lower repair costs. This makes mixing safer, especially with dangerous liquids.

You want machines that work well and do not break a lot. Tengyu makes agitators that last longer and run smoothly. You spend less time and money fixing them. The special blade lets you change the agitator for different jobs. This means you always get the best mixing for each process. The design also helps you see problems early, so you can fix them before they get worse.

Here is a table that shows how Tengyu helps with maintenance:

Benefit | Description |

|---|---|

Longer equipment life | Regular care lowers damage and makes machines last longer. |

Lower repair costs | Finding problems early means you do not pay for big fixes. |

Better production | Smooth running means you work faster and do not stop as much. |

Tengyu’s agitators use strong blades and tough materials. You get steady mixing, even when things are hard. You can trust Tengyu for less downtime and better results.

Here is another table that shows Tengyu’s strengths:

Advantage Type | Description |

|---|---|

Made to handle tough jobs, so it works well in wastewater plants. | |

Special blade technology | Blades can be changed to mix better and last longer. |

Reliable mechanical seals | Stops leaks in harsh places, so it works well and needs less fixing. |

When you use Tengyu, you get strong mixing, fewer leaks, and less fixing. Tengyu helps you keep your work safe, clean, and running well.

You find magnetic agitator technology in many industries. These include pharmaceuticals, chemicals, food, water treatment, biotech, labs, and high-purity places. Each industry gets special benefits. You get cleaner products, safer work, and better quality. Tengyu’s industrial magnetic agitators help you work quickly and safely. The table below shows how smart features make things better:

Key Factors | Efficiency | Safety | Product Quality |

|---|---|---|---|

Automation and Smart Tech | Boosts uptime | Improves safety | Ensures consistency |

Pick Tengyu if you want mixing you can trust and good results for your work.

A magnetic agitator has magnets that turn a mixing blade in a tank. It does not need seals or touching parts. This design keeps your product safe and clean.

You have less chance of leaks and cleaning is easier. Magnetic agitators do not need much fixing. You can count on them for safe and steady mixing in careful jobs.

Yes, you can use them with thick or heavy liquids. Many magnetic agitators work well with these liquids. You should check if the model is strong enough for your job.

You can use Clean-In-Place (CIP) systems to clean it. This lets you wash the agitator without taking it apart. You save time and keep your process safe from germs.