You can pick the best magnetic agitator by matching its features to what you need. People in labs often want to control speed exactly and mix things evenly. Factories need agitators that are strong and have powerful motors for mixing a lot at once. The table below shows that different places need different features:

Application Setting | Key Requirements | Features Needed |

|---|---|---|

Laboratory | Precision and Accuracy | Exact speed control, even mixing, digital screens |

Industrial | High-Volume Stirring Needs | Many stirrers, strong build, powerful motors |

Heavy-Duty Use | Strong stirring plates, sealed motors, good safety systems |

Think about what you need and pick the agitator that helps you reach your goals.

Know your mixing goals. Think about what you want to do with your magnetic agitator. This helps you pick the right one.

Think about the sample you will mix. Liquids and powders need different agitator features.

Match the agitator’s power and speed to your sample’s thickness. Thick samples need more power and faster speeds to mix well.

Pick the right size and shape for your container. Make sure the agitator fits your vessel for the best mixing.

Check how much the agitator can stir. It should handle your sample’s volume without losing performance.

Look for safety and clean features. Agitators with welded seams and smooth surfaces help keep mixing safe and clean.

Plan for cleaning and long-lasting use. Cleaning often and choosing a strong agitator saves time and money later.

Get help from your vendor. Good vendors give support and spare parts so your agitator works well.

Knowing what you need is the first step to picking the right magnetic agitator. Start by thinking about your goal, what you are mixing, and how much power you need. These three things help you find the best agitator for your job.

You should decide what you want to do with your mixing. Different jobs use magnetic agitators for different reasons. For example, in chemical, pharmaceutical, and food work, you may want to:

Make sure everything mixes the same way every time.

Help all the ingredients dissolve so nothing is left out.

Mix different recipes so each part is just like the rest.

Keep the mixing area steady for reactions that need careful control.

Mix things that do not usually go together, like oil and water, to make them smooth.

When you know your goals, you can choose an agitator that helps you reach them. If you need to keep a reaction steady, you might want one with exact speed control. If you need to mix thick stuff, you may need more power.

Always think about what kind of sample you will mix. Liquids, powders, and slurries act in different ways. Thin liquids, like water, are easy to mix. Thick things, like creams or gels, need more force. Some samples have solids that sink fast, so you need an agitator that keeps them moving. If your sample is easy to break, you may want gentle mixing.

Tip: Always check if your sample will react with the agitator’s materials. This stops contamination and keeps your results right.

Mixing intensity means how strong or soft the mixing should be. Some jobs need slow, gentle mixing so the sample does not get hurt. Other jobs need fast, strong mixing to blend things quickly. You should match the agitator’s speed and power to your needs. If you use too much force, you could damage your sample. If you use too little, you might not mix it well.

Picking the right mixing strength helps you get the best results from your magnetic agitator. Think about your goals, your sample, and how much power you need before you choose.

Choosing the right magnetic agitator means you must match it to your sample volume and vessel size. If you pick an agitator that is too small or too large for your container, you will not get good mixing. You want every part of your sample to move and blend well. This helps you get the best results every time.

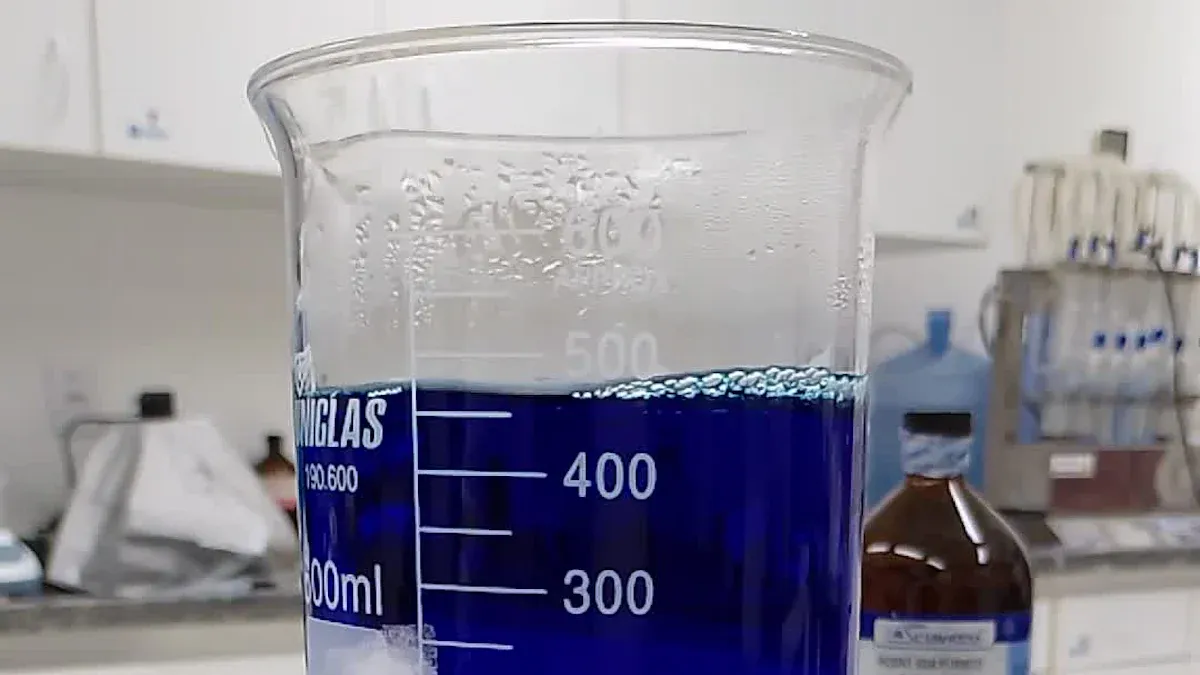

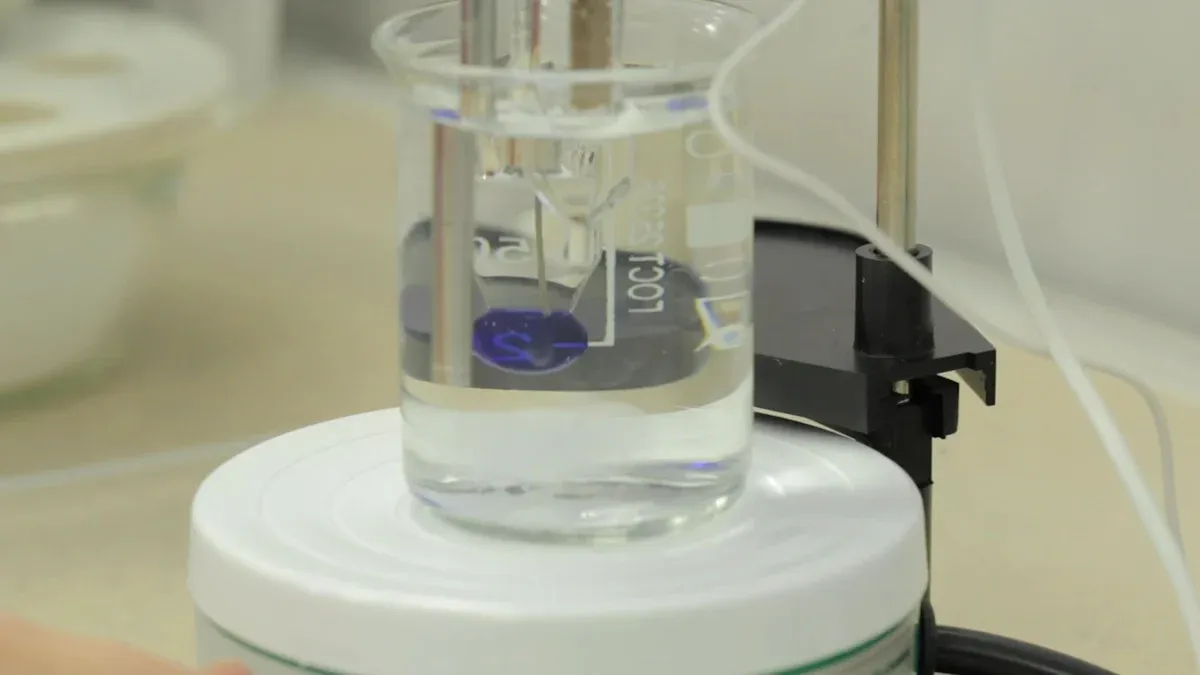

Sample volume plays a big role in how well your agitator works. If you use a spinbar in a large sample, it can mix everything evenly. Spinbars work best when they have enough space to move. For small samples, you need something different. Spinbars do not work well in tiny volumes because they need enough liquid to cover them. In these cases, you might use special small particles for mixing.

Here is a table to help you see how sample volume affects your choice:

Sample Volume | Best Mixing Tool | Why It Works Well |

|---|---|---|

Large (hundreds of mL or more) | Spinbar | Spinbars move freely and mix large samples evenly. |

Small (less than 10 mL) | SPPs | Spinbars need more liquid; SPPs work better for tiny samples. |

Medium (10–100 mL) | Spinbar or SPPs | Both can work, but check your sample needs. |

Mixing also depends on how the liquid flows. Some stir plates make smooth flows, while others create fast, swirling flows. The way your sample moves changes how well it mixes.

You must also think about the size of your vessel. Magnetic agitators work with many vessel sizes, but each has its limits. In labs, you might use small flasks or beakers. In factories, you might use tanks that hold thousands of liters. For example:

You can use magnetic agitators for up to 500 liters in bacterial cultures.

For mammalian cell cultures, you can go up to 3,000 liters.

Some systems work with vessels as large as 20 cubic meters for non-biological uses.

Newer designs can handle up to 30 cubic meters if you need more power.

If your vessel is too big or your sample is too thick, you may need a different type of mixer. Always check if your agitator can handle the size and type of your vessel.

The shape of your container changes how well your sample mixes. Round-bottom flasks help the stir bar move in circles. This shape stops dead zones, so every part of your sample gets mixed. Flat-bottom vessels do not mix as well. The stir bar can get stuck, and some parts of your sample may not move.

Here is a quick look at how shape affects mixing:

Container Shape | Mixing Effectiveness | Dead Zones |

|---|---|---|

Round Bottom Flask | Stir bar moves freely; mixes well | No dead zones |

Flat Bottom Vessel | Stirring is less effective | Dead zones possible |

Tip: Always choose a vessel shape that matches your mixing needs. Round-bottom containers give you better results with magnetic agitators.

You should also check if your vessel material works with your sample and the agitator. Glass, plastic, and stainless steel are common choices. Pick one that does not react with your sample.

Viscosity tells you how thick or thin your sample is. Water has low viscosity. Honey has high viscosity. When you mix thin liquids, you can use a magnetic agitator easily. The stir bar spins without much resistance. You get smooth and even mixing.

Thicker samples need more force. Magnetic stirrers work best with liquids close to water in thickness. If you try to mix something like syrup or gel, the stir bar may stop spinning. The motor cannot push through the thick fluid. You may see the bar jump or stall.

Magnetic stirrers handle low-viscosity samples well.

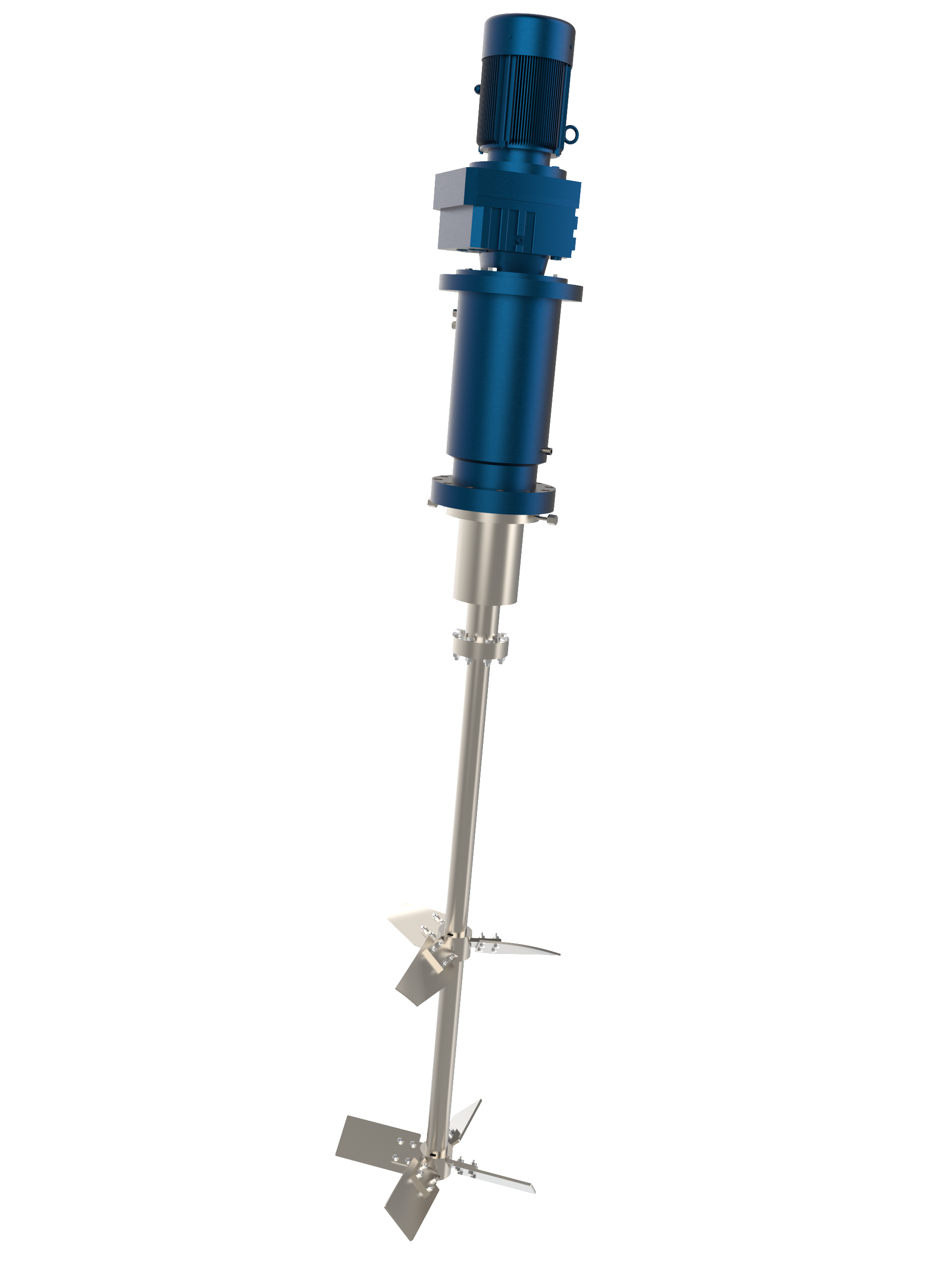

Overhead stirrers work better for high-viscosity samples, especially if the sample gets thicker during mixing.

Magnetic stir bars can stop moving in thick fluids, but overhead stirrers keep turning because they connect directly to the motor.

If your sample starts thin but gets thicker, you should plan ahead. Some chemical reactions, like polymerizations, increase viscosity as they go. You may need to switch to an overhead stirrer for these jobs.

Here is a table to help you decide when to use an overhead stirrer:

Overhead Stirrer | Max. Viscosity (mPa·s) |

|---|---|

OS-S20 | 10,000 |

OS-S40 | 50,000 |

If your sample’s viscosity goes above these numbers, magnetic agitators will not work well. You should choose an overhead stirrer for better results.

Torque means the twisting force that turns the stir bar or paddle. You need more torque for thicker samples. If you use a magnetic agitator with low torque, it may not mix your sample well. The bar can slip or stop. You get uneven mixing.

Mixing thick samples uses more energy. High-viscosity stirrers can reach up to 600 Ncm torque at speeds from 10 to 500 rpm. Some models let you set torque limits, see digital readouts, and run self-tests. These features help you control mixing and avoid errors.

Viscosity changes how much energy you need to mix.

High-torque stirrers handle thick samples better.

Digital controls and torque limits make mixing safer and more accurate.

You may use rheometers or viscometers to measure viscosity. Rheometers test viscoelasticity and have a wide torque range. Viscometers spin a spindle to measure viscosity. They can show errors if the sample is too thick. You should pick the right tool for your sample.

Tip: Always check your sample’s viscosity before choosing a magnetic agitator. If you need more torque, look for overhead stirrers or high-torque models.

If you match the agitator’s torque to your sample’s needs, you get better mixing and save energy. You avoid problems like spinout or stalled bars. You also protect your equipment and get more reliable results.

When you choose a magnetic agitator, you need to look at its main features. These features help you get the best mixing results for your samples. You should focus on stirring capacity, speed range, and stir bar size.

Stirring capacity tells you how much liquid you can mix at one time. Each magnetic agitator has a limit. If you try to mix more than the limit, you will not get good results. You should check the maximum volume listed by the manufacturer. Some models work well with small samples, while others can handle large batches. If you use a magnetic stirrer in a lab, you may only need to mix a few hundred milliliters. In a factory, you might need to mix several liters. Always match the stirring capacity to your vessel size and sample volume.

Tip: If you want to mix thick or sticky samples, pick a magnetic agitator with a higher stirring capacity. This helps you avoid problems like uneven mixing or stalled stir bars.

Speed range means how fast the magnetic agitator can spin the stir bar. You need to pick a speed that matches your sample type. Thin liquids mix well at low speeds. Thick samples need higher speeds to blend properly. Some magnetic stirrers let you adjust the speed with a dial or digital control. This gives you more control over your mixing process. If you use the wrong speed, you may damage your sample or get poor results.

Here are some common speed ranges:

Low speed: 100–300 rpm (good for gentle mixing)

Medium speed: 300–800 rpm (works for most liquids)

High speed: 800–2,000 rpm (needed for fast or vigorous mixing)

You should always start at a low speed and increase slowly. This keeps your sample safe and helps you find the best setting.

Stir bar size plays a big role in mixing. The length of the stir bar should match the size of your vessel and the strength of the magnet inside the magnetic agitator. If the stir bar is too short, it will not move enough liquid. If it is too long, it may spin out or jump around. Spinout happens when the stir bar loses contact with the magnetic field and stops spinning. You can prevent spinout by matching the stir bar to the magnet and vessel.

The way the magnets are set up also matters. Some magnetic agitators use pairs of magnets with opposite poles facing up. This helps the magnetic coupling assembly bind one or more stir bars at higher speeds. Using multiple pairs of magnets can stop spinout and jumping-flea problems.

| Magnet Feature --- Description | | Magnet Orientation --- Magnets have opposite poles pointing upwards. | | Stir Bar Binding --- Magnetic coupling can hold one or more stir bars at high speeds. | | Spinout Prevention --- Multiple magnet pairs prevent spinout and jumping-flea effects. |

Note: Always check the manufacturer’s guide for the best stir bar length for your vessel. This helps you get smooth and even mixing every time.

If you match the stirring capacity, speed range, and stir bar size to your needs, you will get better results from your magnetic agitator. You will avoid common problems and keep your samples safe.

You need to pick the best agitator for your job. Using steps helps you avoid mistakes and get good results. Follow this checklist to help you choose:

Key Considerations | Description |

|---|---|

Understanding Process Requirements | Check what your process needs. Decide if you want gentle or strong mixing. |

Determining Flow Patterns | Think about how your materials move in the tank. |

Pick an agitator that matches your sample’s features. | |

Matching Impeller Design | Make sure the impeller fits your sample’s thickness and density. |

Evaluating Material of Construction | Choose materials that will not react with your sample. |

Check how much power you need for good mixing. | |

Considering Tank Geometry and Size | Match the agitator to your tank’s shape and size. |

Factoring in Operational Flexibility | Decide if you need to mix different products or change settings often. |

Accounting for Maintenance and Lifecycle Costs | Think about cleaning, repairs, and how long the agitator will last. |

First, write down what you want to do. Next, look at your sample and how much you need to mix. Check your vessel’s size and shape. Measure how thick your sample is. Pick an agitator that fits all these needs. Always read the manufacturer’s guide for more details.

Tip: If you are not sure, ask your vendor for help. Many companies can help you pick the right agitator for your job.

Many people make the same mistakes when picking a magnetic agitator. You can avoid problems if you know what to look for:

You do not check how thick your sample is. Thick samples need more power or a different mixer.

You forget to see if the agitator fits your vessel’s size and shape.

You pick the wrong agitator type for your job. Not every agitator works for every process.

You use the wrong material. Some samples react with certain metals or plastics.

You do not check how much power you need. Weak agitators cannot mix heavy or big samples.

You do not think about cleaning and repairs. Hard-to-clean agitators can slow down your work.

You do not plan for changes in your process. If your process changes, your agitator may not work.

Note: Always check your list before you buy. This helps you avoid mistakes and keeps your process working well.

If you pick the right agitator, you get better mixing, save time, and keep your samples safe. Take your time with each step to find the best one for your needs.

It is important to keep things clean when you mix food, medicine, or biotech products. Sanitary agitators stop germs from getting into your product. Welded surfaces help a lot with this. If the seams are welded and the stainless steel is polished, there are fewer places for germs to hide. This makes it easier to clean the equipment and keeps each batch safe.

Most sanitary agitators use polished 304 or 316 stainless steel where they touch your product. Welded seams and smooth surfaces let you wash the equipment well. New ways of polishing make these surfaces even cleaner. This is needed for strict hygiene rules.

Here are some things to look for in a clean design:

Feature | Description |

|---|---|

Sealless Design | No leaks and no holes for a shaft. |

Sterile, Hygienic Mixing | Works with CIP and SIP cleaning. |

Low-Shear, Gentle Agitation | Good for mixing gentle things like proteins. |

Bottom-Mounted Design | No spots where things get stuck. |

SS316L or Hastelloy Construction | Polished for better cleaning. |

Pressurized and Vacuum Vessels | Works in many types of tanks. |

Removable Impellers | Easy to swap for new batches. |

You should also see if the agitator uses magnetic drive technology. This keeps the system from leaking and helps you meet FDA, USDA, and USP rules. Many models are tested so they do not shed bits or cause germs.

Tip: Pick agitators with welded seams and polished surfaces for the best cleaning.

You also need to think about safety, especially if you work with things that can catch fire or explode. Some agitators have special safety labels and features to keep you safe.

ATEX Certification: This means the agitator is safe in places where explosions could happen. You will see the ATEX mark and Ex symbol on these.

Explosion-Proof Stirrers: These are made for places where explosions are possible, like when mixing solvents in factories. They help you stay safe and keep your work going.

If you must follow strict safety rules, always check for these labels before you buy. Explosion-proof and ATEX agitators help you feel safe in hard jobs.

Note: Safety ratings are not just for the agitator—they help keep your whole process safe.

When you choose the right sanitary agitator, you keep your product and your team safe. Clean design and good safety ratings should always be your top choices.

You have to keep your magnetic agitator clean so it works well. Cleaning stops dirt and metal pieces from building up inside. If you work in a lab or factory, you should clean it often. Make a cleaning schedule that fits how much dirt or metal you find. Check your agitator at least every eight hours after you start using it. Set your own rules for how much dirt is okay and when to clean. If you see more dirt than your rules allow, clean it more often. Always stop the product flow before cleaning so you do not mix in new dirt.

Tip: Cleaning your agitator often helps it last longer and saves you money on repairs.

You want a magnetic agitator that will last a long time. Different brands have different features and strengths. Some brands are built strong, while others are easy to use or have new technology. Here is a table to help you compare some popular brands:

Brand | Notable Features |

|---|---|

IKA | Durable, high-precision laboratory equipment |

Heidolph | Innovative features, reliable performance |

Thermo Fisher | Integrated solutions, extensive support |

VWR International | Versatile models for many lab needs |

Benchmark Scientific | User-friendly, affordable |

Corning | Advanced technology, robust build |

Grant Instruments | Customizable, durable in tough environments |

Labnet International | Compact, efficient for small-scale work |

Barnstead | Precise temperature control |

Velp Scientifica | Innovative design, easy to use |

Pick a brand that fits what you need. If you need a tough agitator for hard jobs, choose one with a strong build and good support.

You should think about more than just the price when you buy a magnetic agitator. The total cost includes repairs, energy use, and what happens if it breaks. Here is a table that shows the main things that affect cost:

Cost Factor | Description |

|---|---|

Maintenance | Money you spend on repairs and upkeep |

Energy | Power used during operation |

Downtime | Losses from equipment failure or production stops |

Scalability | Costs if you need to expand or upgrade your system |

Using less energy can save you money over time. If you pick an agitator that uses less power, your bills will be lower. Upgrading to better propellers can also help you save. Most of the money you spend to run your agitator comes from energy use. Even small changes in efficiency can save a lot of money.

Agitators that use less energy lower your power bills.

Better propellers can help you save money fast.

Most of your costs come from energy use, so efficiency is important.

Note: Always think about the total cost, not just the price. A good agitator will save you money over time.

Picking the right magnetic agitator is not just about the machine. You also need help from the company that sells it. Good vendors help you fix problems and keep your agitator working well. They can also help if you need something special. Tengyu is a company that many people trust for this.

When you buy from Tengyu, you get more than just the agitator. You also get help from their team after you buy it. This means you can avoid problems that stop your work. Tengyu’s workers answer your questions fast and help you fix things quickly. They give you advice and help you take care of your agitator.

Here is a table that shows what good vendors like Tengyu offer:

Type of Service | Description |

|---|---|

Spare Parts Availability | You can get spare parts fast, so you do not have to wait long. |

Technical Assistance | You get help with fixing and taking care of your agitator. |

Maintenance Agreements | You can set up regular checks to keep your agitator working well. |

You should check parts that wear out often. Look at bearings and seals when you check your agitator. If you keep extra parts, you can fix things faster if they break.

Tengyu has been making fluid equipment for over forty years. Their team knows how to make agitators that last a long time. Their products work well even in places where things rust or wear down. You can trust them to help you pick the right parts for your job.

Advantage | Description |

|---|---|

Expertise in Fluid Equipment Manufacturing | Tengyu has many years of experience, so you get good products. |

Innovative Designs for Harsh Conditions | Their agitators work well where things rust or wear out. |

Customizable Solutions | Tengyu can change blade shape and materials to fit your job, like in wastewater plants. |

Tip: Always ask your vendor about their help and service before you buy. Good help saves you time and money.

Sometimes, you need something special for your work. Regular agitators may not work for every job. Custom agitators help you get the best results, especially in places like chemical plants or water treatment.

Vendors like Tengyu can make custom agitators for special jobs. Here are some ways custom agitators help you:

You can get mixers that never leak, which is important for dangerous liquids.

Some mixers work in places with high pressure or very hot or cold temperatures.

Custom agitators can mix thick or thin liquids, so you always get good mixing.

New magnetic coupling technology means you do not need seals. This lowers leaks and keeps your sample clean.

Custom agitators are made to be safe and use less energy, which is important in risky places.

Tengyu works with you to make agitators that fit your needs. You can pick the blade shape, size, and what it is made of. This helps you fix problems that regular agitators cannot solve.

Note: Custom agitators give you more control over your work. You get better results and safer mixing when your agitator fits your job.

With good vendor help and custom agitators, your work can go smoothly and safely. Always pick a vendor who helps you and stands by their products.

You can pick the best magnetic agitator by following some easy steps. First, look at what you need the agitator to do. Make sure the agitator has the right features for your job. Always check these important things:

How much it can mix

Safety parts

How thick your sample is

What temperatures it can handle

How exact it is

Use this list to help you choose. Good companies like Tengyu can help you pick the right one. If you follow these steps, you will get better mixing and keep things safe every time.

A magnetic agitator uses a rotating magnetic field to spin a stir bar inside your container. You can mix liquids without touching them. This keeps your sample clean and safe.

You should use magnetic agitators for thin or medium liquids. Thick or sticky samples may stop the stir bar. For heavy mixing, try an overhead stirrer.

Pick a stir bar that matches your vessel size. A short bar may not mix well. A long bar can spin out. Check the manufacturer's guide for the best fit.

Round-bottom containers work best. They help the stir bar move smoothly. Flat-bottom vessels may cause dead zones. Always match your agitator to your container shape.

Remove the stir bar and wash it with soap and water. Wipe the agitator surface with a damp cloth. For tough stains, use a mild cleaner. Dry all parts before use.

Yes, if you choose models with sanitary designs. Look for welded seams and polished stainless steel. These features help prevent germs and keep your product safe.

Check if the sample is too thick. Lower the speed or use a shorter stir bar. Make sure the vessel sits flat on the agitator. If problems continue, contact your vendor.

Many magnetic agitators work with hot liquids. Check the temperature rating before use. Some models have heat-resistant parts. Always follow the manufacturer's instructions.