A magnetic agitator is also called a magnetic stirrer. It helps you mix liquids in a container. You put a small stir bar inside the liquid. The device uses a spinning magnetic field to turn the bar. This keeps your solution moving without touching it. These devices are very important. You can see this by looking at the market size below.

Year | Market Size (USD) | CAGR (%) |

|---|---|---|

2024 | 355 million | N/A |

2035 | 648 million | 5.62 |

Key Takeaways

A magnetic agitator mixes liquids with a stir bar. It uses a spinning magnetic field to do this.

These devices are very important in labs. People use them to mix solutions, grow cell cultures, and prepare samples.

Magnetic stirrers stop contamination. The stir bar stays inside the liquid. This keeps it away from outside things.

They need little care because they have no seals. This lowers the chance of leaks and damage.

Magnetic agitators mix gently. This is good for sensitive samples and delicate solutions.

They help save time and space in the lab. They mix faster than stirring by hand. They fit well on busy lab benches.

Picking the right container and stir bar size is important. This helps the magnetic agitator mix well.

Magnetic agitators can be used in many areas. People use them in biotech, medicine, and food production.

Magnetic Agitator Basics

What Is a Magnetic Agitator

You see a magnetic agitator in labs when mixing liquids. This device is also called a magnetic stirrer. It uses a small bar called a stir bar. The stir bar sits inside the liquid. The magnetic stirrer makes a spinning magnetic field. This field makes the stir bar spin. The spinning bar mixes your solution.

A magnetic stirrer is a lab tool. It uses a spinning magnetic field to turn a stir bar in a liquid. This helps you mix and blend solutions.

You can use a magnetic agitator for many jobs. It mixes solutions for tests, grows cell cultures, and gets samples ready for chemical tests.

Sometimes, you may use a stirring hot plate. This tool can heat and stir at the same time. It helps keep your solution warm while mixing.

Magnetic Stirrer Principle

The way a magnetic stirrer works is simple but strong. The device uses a spinning magnet or electromagnets. These make a spinning magnetic field. When you put the stir bar in your container, the field makes it spin. The spinning bar stirs your liquid and keeps it mixed.

The magnetic stirrer works because of magnetic pull and push.

The stir bar spins fast because of the spinning field.

This way, you can mix liquids without touching them. This helps stop contamination.

This method makes the magnetic agitator good for small amounts and gentle mixing. You can use it for experiments that need careful temperature, cell cultures, and soft chemical reactions. The magnetic stirrer keeps your solution moving smoothly.

Key Features

When picking a magnetic agitator, look for special features. Good magnetic stirrers have many benefits:

They use a magnetic field to mix, not a motor.

The stir bar does not touch the outside, so your solution stays clean.

Magnetic agitators do not rust, even with strong chemicals.

You do not need to fix them much because there are no open moving parts.

They are great for gentle mixing, so you can use them with soft materials.

Tip: Magnetic stirrers save time and space in the lab. They mix faster than by hand and fit on crowded benches.

Here is a table that shows the main benefits of using a magnetic stirrer for small and gentle mixing:

Advantage | Description |

|---|---|

Space Efficiency | Mini magnetic stirrers are small, good for tiny labs. |

Time-Saving | They mix much faster than stirring by hand. |

Versatility | You can use them with many liquids, thick or thin. |

Reduced Contamination Risk | The stir bar stays in the liquid, so there is less chance of contamination. |

The way it works and these features make the magnetic agitator a top pick for many lab jobs. You get gentle, steady, and good mixing every time.

Main Components

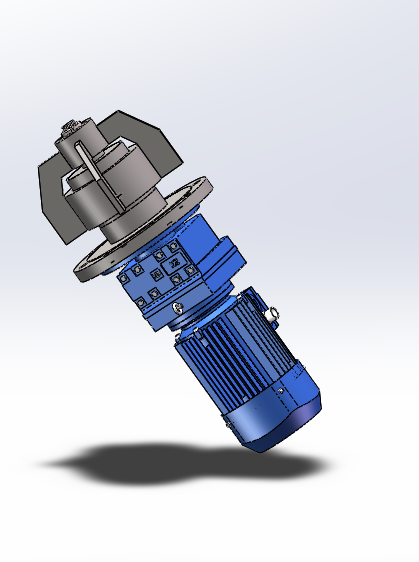

Magnetic Drive

The magnetic drive is the main part of a magnetic agitator. It makes the spinning magnetic field that moves the stir bar. Most magnetic drives use strong magnets or electromagnets inside. You do not see any moving parts on the outside. This helps keep your liquid safe from leaks and germs.

A seal-less design works best for the magnetic drive. This means there are no leaks, so your product stays clean. You can use magnetic agitators in places with high pressure or no air. The drive does not need seals that can break. This also means you do not have to fix it often.

Here is a table that shows why the magnetic drive works so well:

Feature | Description |

|---|---|

Seal-less Zero Leakage | Stops leaks and keeps your product clean. |

High-pressure Safe | Works in tough labs with high pressure. |

Non-contaminating Mixing | Keeps your liquid clean while mixing. |

Low Maintenance | Needs less fixing and checking. |

Low Cost of Ownership | Saves money over time. |

Tengyu engineers use special seal-less designs for magnetic drives. You get a safe, easy, and strong mixing tool.

Stir Bar

You put the stir bar inside your container. This small bar is sometimes called a "flea." It spins when the magnetic drive makes a field. The stir bar mixes your liquid gently and evenly. You can pick different shapes and sizes for your stir bar.

New ideas have made stir bars better and stronger. Some spinbars have a center point to help them spin better. This gives you better mixing for many lab jobs. Some stir bars have PTFE coating to last longer and fight chemicals. There are smart stir bars that check speed and temperature. These features help you mix better and make your work easier.

Here are some new things you might see in stir bars:

Spinbars with a center point for better mixing.

Smart bars that change speed and temperature.

PTFE-coated bars for longer life and chemical safety.

Mini stir bars for mixing very small amounts.

Digital controls to help you watch your mixing.

Tengyu makes stir bars with strong materials and smart features. You get good mixing and a longer-lasting product.

Container

You need the right container for your magnetic agitator to work well. Most people use flat-bottomed containers because they work best with round stir bars. If you use a round-bottomed flask, you may need a smaller stir bar so it does not get stuck.

Containers come in many types of materials. You want a container that does not break down with chemicals and lasts a long time. Here is a table that shows common materials and what they are used for:

Material | Properties | Applications |

|---|---|---|

Stainless Steel | Strong, does not rust | General mixing, chemical dosing |

Hastelloy | Handles strong chemicals, lasts long | Chemical industry |

Titanium | Light, resists seawater and acids | Water treatment, desalination |

Polypropylene | Not metal, good for harsh chemicals | Chemical, plastics industries |

Duplex/Super-Duplex | Handles tough environments | High-temperature mixing |

Tengyu engineers pick the best materials for your needs. You get containers that last and keep your liquid safe.

Sealing

Sealing plays a key role in the performance of your magnetic agitator. You want to keep your liquids safe and your equipment running smoothly. A good seal stops leaks and blocks outside germs or dust from getting into your solution. This is very important when you work with sensitive or dangerous chemicals.

You will find that magnetic agitators use a special type of seal called a magnetic shaft seal. This seal creates a tight, hermetic barrier between the inside of your container and the outside world. You do not need to worry about leaks or spills. The magnetic seal keeps everything inside, even when you mix at high speeds or under pressure.

Here are some ways effective sealing helps you during operation:

Magnetic shaft seals form a hermetic seal. This keeps your solution pure and stops outside contamination.

You avoid leaks, even when you work with hazardous or valuable liquids.

Magnetic seals last a long time. Some have worked since 1983 without leaking or needing repairs.

You save money because you do not need to replace seals often or stop your work for maintenance.

You get peace of mind knowing your lab or plant stays safe and clean.

Note: Magnetic seals replaced old mechanical seals in many labs and factories. You get lower costs and less downtime because magnetic seals do not wear out as fast.

Tengyu engineers focus on making seals that work in tough conditions. They use strong materials and smart designs. You can trust their magnetic agitators to keep your liquids safe, even in high-pressure or high-temperature jobs. Their seal-less technology means you do not have to worry about leaks or contamination.

You may notice that magnetic agitators do not have moving parts that touch the outside. This design helps the seal last longer. You do not need to check or fix the seal as often as you would with older systems. You also avoid the risk of germs or dust getting into your solution.

When you choose a magnetic agitator with a good seal, you protect your samples and your equipment. You also make your work safer and easier. Sealing is not just a small part—it is a big reason why magnetic agitators work so well in labs, chemical plants, and other sensitive places.

Here is a quick table to help you see the benefits of magnetic sealing:

Benefit | What It Means for You |

|---|---|

No Leaks | Your liquids stay inside the container. |

No Contamination | Your samples stay pure and safe. |

Long Service Life | You spend less time and money on repairs. |

Safe for Hazardous Use | You can mix dangerous chemicals safely. |

With strong sealing, you get reliable mixing and a safer workspace. You can trust your magnetic agitator to protect your process every step of the way.

Operation

How It Works

When you use a magnetic stirrer, you place the device on a flat surface. You put your container with liquid on top. Inside the container, you drop the stir bar. The magnetic base creates a spinning magnetic field. This field makes the stir bar spin quickly. As the bar turns, it mixes your solution smoothly and evenly. You do not need to touch the liquid, so your sample stays clean.

Tip: Always start the magnetic stirrer at a low speed. Increase the speed slowly. This helps the stir bar stay connected to the magnetic field and prevents splashing.

Setup Steps

You can set up your magnetic stirrer in a few simple steps:

Place the magnetic stirrer on a stable, flat surface.

Choose a clean container that fits well on the base.

Select the right stir bar for your liquid and container size.

Add your liquid to the container.

Drop the stir bar into the liquid.

Center the container on the magnetic stirrer.

Turn on the device and set the speed. Start slow, then increase as needed.

If you notice the stir bar stops spinning, check if it is centered and properly coupled to the base. For thick or sticky solutions, try a shorter stir bar or a stronger magnetic base. If mixing looks uneven, use a longer or differently shaped stir bar, like a triangular one, to improve the mixing.

Maintenance

You want your magnetic agitator to last a long time. Regular care keeps it working well. Here are some best practices for maintenance:

Check the stir bar and container for wear or damage. Replace them if needed.

Make sure all parts are lined up correctly to avoid extra wear.

Balance the components to reduce vibration.

Watch the speed, pressure, and temperature every day to catch problems early.

Lubricate any moving parts if your model requires it.

Tighten bolts, screws, and clamps often.

Inspect the shaft for bending or misalignment.

Look at the impeller for damage to keep mixing strong.

Check electrical connections for loose wires or wear.

Do visual checks for signs of damage.

Use vibration analysis to spot hidden issues.

Test the oil if your agitator has bearings.

Run electrical tests to make sure everything works right.

Note: If you ever have trouble or need help, Tengyu offers expert support and service. Their team can guide you through setup, troubleshooting, and repairs.

A good maintenance routine helps your magnetic stirrer work better and last longer. You save time and money by preventing big problems before they start.

Advantages

No Mechanical Wear

You do not need to worry about parts wearing out. A magnetic agitator uses a spinning magnetic field to move the stir bar. There are no gears, shafts, or seals rubbing together. This means there is no friction from moving parts. You avoid problems that happen when things rub and wear down.

Magnetic agitators do not have moving parts or seals that wear out.

Your equipment lasts longer because nothing grinds away.

Less wear means you do not fix or replace parts as often.

You also lower the chance of contamination, which is important for sensitive samples.

Mechanical agitators break more often because their parts wear out. You can count on magnetic agitators to last longer and work better.

Low Maintenance

You save time and money with magnetic agitators because they need little care. The sealless design means you do not need mechanical seals. Mechanical seals often break in other agitators. You do not have to stop your work to fix leaks or change seals.

Magnetic agitators do not need seals, so you do not buy or change them.

You avoid stopping work because of seal problems.

You spend less on repairs and new parts.

Your work keeps going without delays.

Mechanical agitators need lots of checks and repairs. With magnetic agitators, you can focus on your work, not fixing equipment. This helps you get more done with less trouble.

Tip: If you want to spend less on maintenance and work faster, pick a magnetic agitator instead of a mechanical one.

Gentle Mixing

Magnetic agitators give you gentle and careful mixing. You can change the speed to control how fast the stir bar spins. This helps protect delicate samples and sensitive solutions. You do not have to worry about breaking your materials.

Gentle mixing keeps your samples safe. You can mix cell cultures, light suspensions, or chemical solutions without harming them. Magnetic agitators let you control the mixing for careful jobs.

The table below shows how magnetic agitators and mechanical agitators compare for gentle mixing:

Feature | Magnetic Agitators | Mechanical Agitators |

|---|---|---|

Adjustable Speed | Yes | Sometimes |

Gentle Action | Yes | No |

Sample Protection | High | Low |

Efficiency | High | Medium |

You also use less energy because the system runs smoothly. It does not waste power on friction. This makes magnetic agitators a smart choice for labs that want to save energy and work better.

Contamination Prevention

You want your samples to stay pure and safe. Magnetic agitators help you do this better than other mixers. They keep germs and dust out of your liquid. The design seals everything inside the container. You do not need to open the system or touch the liquid while mixing.

Mechanical agitators use seals and shafts that go through the container wall. These parts can break or wear out. When this happens, germs or dirt can get into your solution. You might also see leaks or spills. This is a bigger problem when you mix sensitive or costly liquids. Magnetic agitators fix this issue. The stir bar spins inside the container. It is powered by a magnetic field from outside. No part of the drive touches your liquid.

Nicole Zangl, a Senior Expert at ZETA, says switching to magnetic technology lowers the risk of batch contamination in bioreactors and mixing vessels. You get safer mixing and better results.

You can see how each mixer works in this table:

Mixer Type | Risk of Contamination | Reason |

|---|---|---|

Magnetic Agitators | Very Low | No seals or shafts in contact with liquid |

Mechanical Agitators | High | Seals and shafts can leak or wear out |

A study in ScienceDirect found that magnetic stirring mixes better than orbital shaking. This means you get better mixing and fewer spots where germs can hide. Good mixing helps stop contamination before it starts.

Here are some reasons why magnetic agitators keep your samples clean:

The sealed design blocks air, dust, and germs.

You do not need to open the container to move the stir bar.

No moving parts go through the container wall.

You avoid leaks and spills that can ruin your work.

You can use magnetic agitators for careful jobs, like cell cultures or drug mixing.

Mechanical agitators cannot keep your samples as safe. You may need to clean or change seals often. Every time you open the system, germs can get in. Magnetic agitators let you mix without worry.

Tip: If you work with valuable or sensitive solutions, pick magnetic agitators to keep your samples safe from contamination. Tengyu’s seal-less designs give you extra safety and peace of mind.

Applications

Laboratory Use

You see magnetic agitators in almost every lab. They help mix liquids that are not thick. These devices work fast and mix evenly. You can use them for many daily lab jobs. They help make chemical solutions, dissolve powders, or mix samples for tests. Magnetic stirrers are important in labs because they mix the same way every time. You can set them to work alone, so you do not need to watch them. This saves you time and lets you do other experiments.

Some common lab jobs that use magnetic agitators are:

Mixing buffer solutions for experiments

Making culture media for growing cells

Dissolving salts or powders in water

Mixing samples for chemical analysis

Hotplate magnetic stirrers can heat and mix at the same time. This helps reactions go faster or keeps solutions warm. Small models, like the Benchmark Magnetic Stirrer, fit on busy lab benches and spin liquids quickly.

Tip: Use magnetic agitators when you want gentle, hands-free mixing for small amounts.

Chemical Mixing

You can use magnetic agitators to mix chemicals in labs and factories. These devices do not touch the liquid, which keeps things clean and safe. The sealed design stops leaks and keeps dangerous or sensitive materials inside. Industrial magnetic agitators meet high hygiene rules, like ASME BPE and EHEDG. This makes them good for mixing chemicals that must stay pure.

Here are some ways magnetic agitators help with chemical mixing:

They stop contamination by keeping the mixing closed.

The sealed design stops leaks, even with dangerous chemicals.

You can mix small or gentle batches safely.

They work well for clean jobs, like in medicine or biotech.

You can trust magnetic agitators for hard jobs where safety and cleanliness are important.

Biotech and Pharma

In biotech and drug making, you must keep products clean and safe. Magnetic agitators are very important in these fields. They use a magnetic coupling system that stops leaks and keeps the process closed. This design removes the problems of mechanical seals.

You will see magnetic agitators used for making drugs, biologics, and other careful jobs. These mixers follow strict rules, like GMP, FDA, and USP. They give you leakproof, clean mixing that protects your valuable products.

Here is a table that shows why magnetic agitators are great for biotech and pharma:

Feature | Description |

|---|---|

Sterility | Makes sure mixing is clean and safe |

Design | Magnetic coupling system stops leaks |

Applications | Good for drug making and biologics |

Compliance | Follows strict industry rules |

Magnetic coupled mixers have changed how companies mix sensitive materials. You can count on them for safe, clean work. Tengyu has experts who design agitators that meet the highest standards for these fields.

Food and Beverage

You find magnetic agitators in many food and drink factories. These devices help mix liquids and ingredients safely. You want your food to stay pure and fresh. Magnetic agitators help you do this.

When you use a magnetic agitator, you do not need seals or shafts in the tank wall. The magnetic drive spins the stir bar inside the tank. It does not touch the outside. This keeps germs and dust away from your food. Your product stays safe from contamination. The taste and quality stay high.

Food labs often mix small batches or gentle solutions. Magnetic agitators are great for these jobs. You can blend flavors, dissolve powders, or keep sauces smooth. You can also mix vitamins or colors into drinks. The gentle mixing does not break sensitive ingredients. You keep the texture and color just right.

Here are some ways magnetic agitators help in food and drink production:

Mixing syrups for soft drinks

Blending dairy products like milk or yogurt

Dissolving sugar or salt in water

Keeping sauces or dressings smooth

Mixing vitamins or minerals into health drinks

Preparing samples for quality control tests

Tip: Use magnetic agitators to keep food clean and safe from germs. The sealed design helps you follow food safety rules.

Magnetic agitators also save you time and money. You do not stop work to fix seals or clean shafts. The stir bar is easy to take out and clean. You can switch batches fast. This helps you make more products in less time.

The table below shows how magnetic agitators help in food and drink production:

Benefit | What It Means for You |

|---|---|

No Seals Needed | No leaks or outside contamination |

Easy to Clean | Fast changeover between batches |

Gentle Mixing | Protects delicate flavors and textures |

Consistent Results | Every batch tastes the same |

Tengyu engineers make magnetic agitators for food and drink factories. They use strong, food-safe materials. You get mixers that last long and meet hygiene rules. Tengyu can help you choose the right agitator for your job, whether you make drinks, sauces, or dairy foods.

You want your food and drinks to be safe and taste good. Magnetic agitators give you the safety and control you need. You can trust them for small lab jobs or big factory tanks. With magnetic agitators, your products stay pure, your work goes smoothly, and your customers are happy.

Magnetic Agitator vs. Other Mixers

Magnetic Stirrer vs. Mechanical Agitator

When you look at a magnetic stirrer and a mechanical agitator, you see big differences. A magnetic stirrer uses a spinning magnetic field to move a stir bar inside your container. No moving parts touch the liquid. This keeps your samples clean and safe. Mechanical agitators use shafts, blades, or paddles that go into the liquid. These parts can wear out and might cause leaks or contamination.

A magnetic stirrer is best for small amounts, usually up to 20 liters. It gives gentle mixing, which is good for sensitive samples. Mechanical agitators can mix bigger amounts, even up to 80 liters or more. They work well for thick or sticky liquids. If you need to mix something heavy or in a big tank, mechanical agitators might be better. But if you want less work and cleaner mixing, a magnetic stirrer is a great choice.

Feature | Magnetic Stirrer | Mechanical Agitators |

|---|---|---|

Volume Range | Up to 20 L | 2–80 L or more |

Maintenance | Very Low | High |

Contamination Risk | Very Low | Higher |

Mixing Strength | Gentle | Strong |

Best Use | Small, sensitive | Large, viscous |

Tip: Pick a magnetic stirrer for small, gentle jobs. Use mechanical agitators for big or tough mixing tasks.

Magnetic Stirrer vs. Static Mixer

A static mixer works in a different way than a magnetic stirrer or a mechanical agitator. It does not have any moving parts. Instead, a static mixer has fixed baffles or tubes inside a pipe. When you push liquid through, the baffles make the liquid mix. This is good for mixing liquids in pipes all the time.

A magnetic stirrer lets you control the speed and watch the mixing. Static mixers are good for quick, simple blending, but you cannot change them while they work. If you need to mix small batches or want to keep things clean, a magnetic stirrer is better. Static mixers are best for big flows and when you do not need to change the mixing.

Choosing the Right Mixer

You should think about a few things before picking a mixer. Here are some important points:

How much liquid you need to mix

The shape of your container

How thick your liquid is

If you need to heat your sample

What kind of mixing you want

How much force your sample can take

A magnetic stirrer is best for small amounts and gentle mixing. Mechanical agitators are good for bigger jobs and thick liquids. Static mixers work well for mixing liquids in pipes.

You should also check these things when picking a mixer:

Criteria for Selecting a Mixer | Description |

|---|---|

Compatibility with Bag Films | Make sure your mixer works with your container materials. |

Application Versatility | Pick a mixer that fits both small and large jobs. |

Specific Mixing Applications | Choose based on what you need to mix. |

Closed System Maintenance | Keep everything sealed to avoid contamination. |

Equipment Design Requirements | Check if you need special equipment or disposable parts. |

Impact of Vessel Shape | Remember that square vessels mix better than round ones. |

Testing and Validation | Test your mixer to find the best settings. |

Understanding Product Characteristics | Know your liquid’s properties and make sure the mixer matches. |

If you work with small or sensitive samples, a magnetic stirrer gives you the most control and safety. For big or factory mixing, mechanical agitators or industrial magnetic agitators may be better. Tengyu can help you compare choices and pick the right mixer for your job.

A magnetic agitator and a magnetic stirrer help you mix things easily. They keep your samples clean and do not wear out fast. These tools work best in labs or for gentle mixing. You can trust them when you need pure samples.

They save energy and are simple to use. You get good results in places that need care.

Industrial magnetic agitators can be set up in many ways for different jobs.

For the best mixing, think about what you need. You can ask Tengyu’s experts for help with your special mixing problems.

FAQ

What is the main use of a magnetic agitator?

You use a magnetic agitator to mix liquids in a container. It helps you blend solutions evenly without touching them. This keeps your samples clean and safe.

Can you use a magnetic agitator with any type of liquid?

You can use a magnetic agitator with most thin or medium liquids. Thick or sticky liquids may not mix well. For heavy mixing, you may need a different type of mixer.

How do you clean a magnetic stir bar?

Remove the stir bar from the container. Wash it with soap and water. For tough stains, use alcohol or a mild solvent. Dry it before using it again.

What size stir bar should you choose?

Pick a stir bar that fits your container. A longer bar works better for bigger containers. For small containers, use a short bar. Make sure the bar can spin freely.

Do magnetic agitators need a lot of maintenance?

You do not need much maintenance. Check the stir bar and container for damage. Clean them after each use. Inspect the device for dust or spills. This keeps your agitator working well.

Can you heat liquids while using a magnetic agitator?

Yes, you can. Many magnetic agitators have a built-in hot plate. You can heat and mix your solution at the same time. Always watch the temperature to avoid overheating.

What should you do if the stir bar stops spinning?

Check if the stir bar is centered in the container. Lower the speed and try again. If it still does not spin, use a different bar or check the magnetic base for problems.

Are magnetic agitators safe for sensitive samples?

Yes, they are. The sealed design keeps out germs and dust. You do not touch the liquid while mixing. This makes magnetic agitators safe for delicate or valuable samples.

How To Clean Caustic Soda Diaphragm Pumps

Caustic soda diaphragm pumps are essential equipment used in industries like chemical processing, wastewater treatment, and food production, where they handle harsh, caustic fluids. These pumps are designed to transfer caustic soda and other corrosive liquids, making them crucial for maintaining fluid flow in various applications.

Read More

Magnetic Drive Pump Vs Centrifugal Pump

Pumps are essential in industries like chemical, pharmaceutical, and water treatment, where they transfer fluids and maintain system efficiency. Choosing the right pump is crucial for optimizing performance and ensuring safety. Magnetic drive pumps and centrifugal pumps are two widely used types, each with its own advantages.

Read More

Magnetic Drive Pump Problems

Magnetic drive pumps are widely used in industries such as chemical processing, pharmaceuticals, and water treatment due to their leak-free operation, energy efficiency, and reliability. They are specifically designed to handle hazardous and corrosive fluids safely, making them essential for maintaining safety and efficiency in critical applications.

Read More

Magnetic Drive Pumps Manufacturers

Magnetic drive pumps are essential in industries such as chemical processing, pharmaceuticals, water treatment, and food processing, where handling hazardous, corrosive, or toxic fluids safely is a top priority. These pumps are valued for their leak-free operation and hermetically sealed design, which eliminates the need for traditional shaft seals, preventing leakage and contamination.

Read More